PROBLEM SHARED

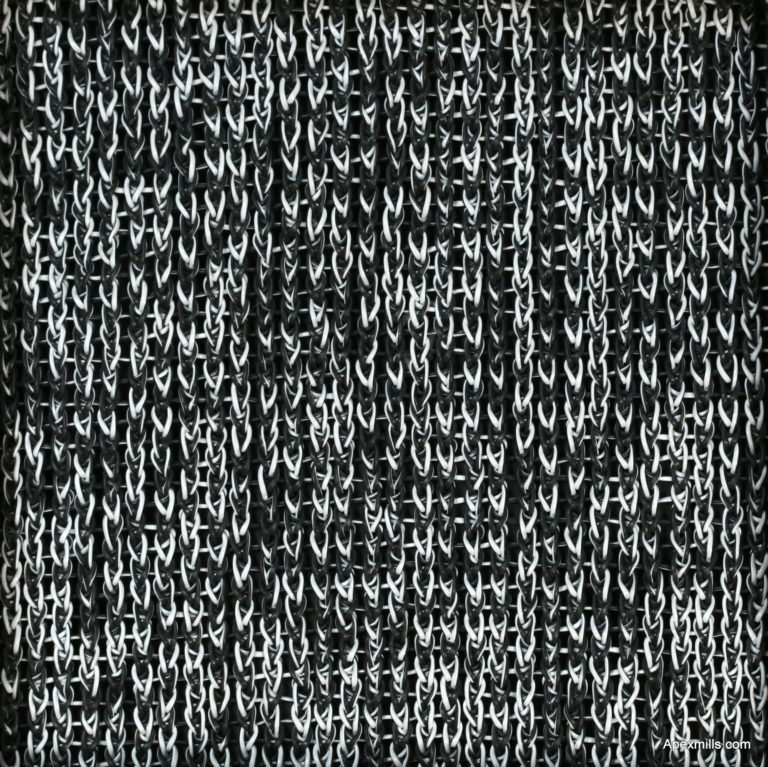

A leading designer of high-end woven vinyl accessories and home furnishings wanted to augment their product line with an alternative to woven goods. Intrigued by the durability of the knitting process, they sought to reduce the amount of fraying and fabric loosening that sometimes occurs in weaves.

PROBLEM SOLVED

Using a variation of the vinyl yarn currently used by the designer, Apex Mills engineers were able to modify the knitting machines and process to accommodate the heavier and less pliable vinyl yarn. Working together, we were able to maintain the unique fabric properties in which the company has built their reputation.

RESULT REALIZED

Not only was this luxury home accessories and furnishings manufacturer able to extend the depth of their existing product line, they were able to expand the breadth of products offered because of the increased strength and stability provided by the custom tailored warp knit process.

Reach your most challenging

textile goals with confidence.