Apex Mills manufactures solid knit fabrics with a wide range of breathability and flexibility. Knitted with interlocking stitches, our experienced technicians can alter the shape and size of these loops to create a spectrum of elongation qualities. We can construct solid knits that are completely stable or we can design solid knits with a great deal of stretch in width, length or bias. Solid knits breathe. Even the densest, most solid appearing knits have tiny openings, allowing the flow of air. The potential variability in sold knit fabric design allows the experienced team of Apex Mills to create an enormous range of products to meet our customers’ diverse needs.

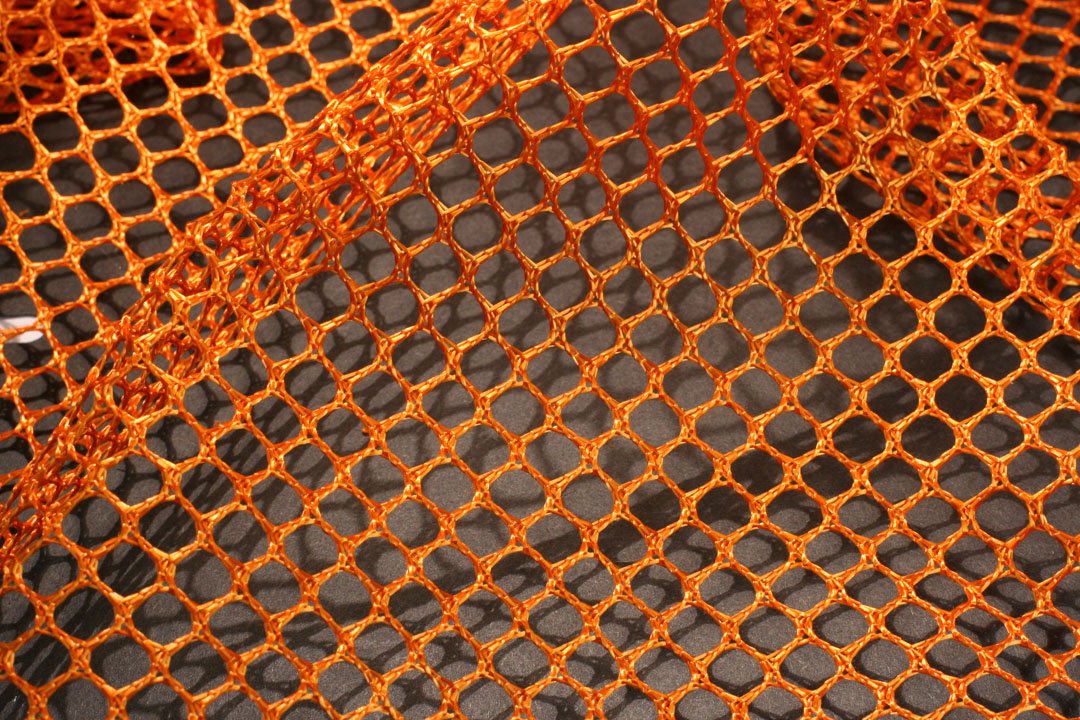

We create mesh netting fabrics with an almost unlimited variety of shapes and sizes. The advantage of mesh and net fabrics reside in their strength-to-weight ratio. These technical textiles can be lightweight, but remarkably tough and tear resistant. As one of the leading producers of mesh and netting in the United States, Apex Mills’ breadth and depth of experience allows us to vary the porosity of mesh and netting properties to meet highly specific applications. We can tighten the loops to create a filter fabric that allows water to pass through while capturing tiny particulates. We can use high elongation or elastomeric yarns to make fabrics with significant stretch and recovery.

3D spacer fabrics offer some of the most innovative solutions of today. Because of our ability to design two distinct fabric surfaces along with the variability of connecting spacer yarns and thicknesses, an almost limitless variety of application solutions are within our reach. One great appeal of 3D spacer fabric is that it can, in some applications, replace foam that degrades, yellows and is not environmentally friendly. 3D spacers allow for tremendous breathability, and we can vary the elongation and stability of the yarns to customize your solution.

The most important characteristic of stretch fabric is its ability to return to the original shape after force has been applied. Apex Mills has extensive experience manufacturing flexible stretch fabrics in our production facilities. We can produce both high and low modulus fabrics depending on your need. After production, our facilities are equipped to provide custom finishing options like anti-microbial or fire retardant solutions. We use rigorous testing to ensure our elastics meet your stretch specifications.

Ask us about EcoRich™ - our environmentally friendly post-consumer recycled and bio-derived yarns.

Our Fire Retardant fabric provides enhanced protection and safety meeting certification standards NFPA 701, FAR 25.853, ASTM D6413 and EN 1021

Antimicrobial fabric is tested for long-lasting benefits using yarn based or topical solutions to reduce odor and inhibit bacteria growth

Our DRYRun™ family of fabrics help to wick moisture away, keeping you drier and more comfortable, or repel moisture keeping you and the fabric dry

Our abrasion resistant fabric prevents tears and surface wear keeping the fabric intact and adding protection

Textiles are far more sophisticated than sweaters and cotton cloth. With applications in fields as wide ranging as aerospace, automotive, biodiversity and health care, the broad range of qualities and characteristics that textiles offer, make them a perfect solution for challenges from simple to complex. Some are tough, some are soft, some are stretchy, some are all of these. Some help clean polluted water. Some prevent burns. Some hold airplane parts together. Others camouflage soldiers in combat. Apex Mills specializes in designing the right fabric construction for the application in which it will be used.

Fill Out Our Questionnaire

Yarns are the building blocks of textiles. At Apex Mills, we work with yarn makers to create yarns specific to each customer's needs. Apex Mills uses only synthetic yarns, which are created by heating and softening polyester chips, then spinning and extruding them in long continuous filaments.

A yarn might be monofilament-like fishing line, or it can use combinations of multiple filaments spun together forming yarns with various properties. These multifilament yarns create fabrics with unique structure, such as increased stretchiness, greater porosity, or varying degrees of softness, toughness, luster or pliability. Some yarns may consist of over a hundred filaments spun together, making the end fabric softer and more plush. In essence, the higher the filament count, measured in deniers, the softer the fabric will be.

Fill Out Our Questionnaire

Yarns have different lusters-degrees of brightness. Most yarns in cross section are round, but a cross section of a tri-lobal yarn looks like a triangle with concave sides, which produce the most reflective fabrics. Vests for highway workers are made with tri-lobal yarns, so that they may be as bright as possible. Yarns can have hydrophilic properties designed into them, to wick water away, or they can have antimicrobial elements added, to avoid unpleasant odors. Now, many yarns are being recycled adding environmental friendliness to their attributes. Over 70 years of industry knowledge lets Apex Mills quickly understand the best yarns for their customers' needs.

Yarn choice is critical in a fabric, but, in the U.S., most major textile mills buy materials from the same yarn makers. When yarns come through Apex Mills' doors, that's where the magic begins. That's where spools of yarn become something more than what our competitors offer. Apex Mills does not weave its textiles. We use only warp knitting because of the advantages it provides over other techniques.

Fill Out Our Questionnaire

Woven fabrics are made from threads running vertically and horizontally (think a broadcloth shirt) which leaves little room for variation in porosity and almost no room for stretch. Warp knitting, the linking of stitches and loops (think of a quality golf shirt), frees designers to vary the fabric's architecture in ways that affect elasticity, porosity, durability, coarseness or smoothness. Warp knitting allows for the production of much wider sheets of fabric than circular knitting or weaving. It creates fabrics much less likely to sag, shrink or ravel. And, warp knitting allows Apex Mills to create three different kinds of fabric: solid knit, mesh/netting and 3D spacer fabrics.

Warp knitting involves attaching sometimes thousands of yarn filaments side by side on a long metal spool called a beam and winding them together. It's critical that all the filaments are wound onto the beam at the same tension to prevent defects in the fabric. It is a scientific process and requires the skills of a trained technician to thread the machine properly. When you watch someone knit a sweater, they move horizontally, one row of loops and stitches at a time. A warp knitting machine knits vertically by using thousands of needles to create thousands of loops and stitches simultaneously.

By varying the type of yarns used and how, and by altering the movement of the needles, Apex Mills can create solid knit or mesh knit fabrics with loop openings of differing shapes and sizes. The machines provide enormous flexibility, so that vastly different textiles can be produced from the same process.

Warp knitting also allows us to create 3D spacer fabrics, which are replacing foam in many applications because they're more durable and environmentally kind. These fabrics consist of two layers of multifilament mesh knits connected with lengths of thick spacer fibers-often springy monofilament-to create a thicker, bouncier fabric that allows for air movement between the layers. These fabrics are useful in office furniture, military backpacks, running shoes and automotive seats that feature blown air circulation.

The fabric that rolls off the warp knitting machine is called greige (pronounced "gray"). Some greige fabrics are used as is but a considerable number of Apex Mills textiles require finishing. When customers want colored fabrics, the greige is placed in a jet-dye tank and subjected to heat and pressure so that the injected dyes take evenly and are colorfast.

A mesh knit fabric will naturally want to compress like an accordion. These fabrics require tenting, a process whereby the fabric edges are pinned to parallel rails which can be widened or narrowed to provide the preferred elongation, stretch and smoothness of the fabric. It is then run through heating ovens precisely regulated at pre-determined temperatures that Apex Mills engineers know will set the fabric's stretch memory. We're able to create various textiles with the precise elongation and elasticity our customers want them to have.

Fill Out Our Questionnaire

At this point, fabrics may be treated with other applications according to the customer's needs: antimicrobial elements, flame retardant chemicals, UV treatment to prevent color fading, or resins to make the fabric stiffer.

Nobody has the breadth of capability that Apex Mills has. We can produce a fabric that weighs a half-ounce per linear yard, or one that weighs 25 ounces per linear yard. Using the same type of machinery and processes-but intricate permutations learned from 70 years of continuous innovation-Apex Mills was able to produce 800 different textiles last year alone. Fill Out Our Questionnaire

Your privacy is very important to us. Accordingly, we have developed this Policy in order for you to understand how we collect, use, communicate and disclose and make use of personal information. The following outlines our privacy policy.

We are committed to conducting our business in accordance with these principles in order to ensure that the confidentiality of personal information is protected and maintained.