PROBLEM SHARED

One of the nation’s largest suppliers of patient lift slings had a fabric problem that was creating a potentially dangerous condition for the patients using them.

PROBLEM SOLVED

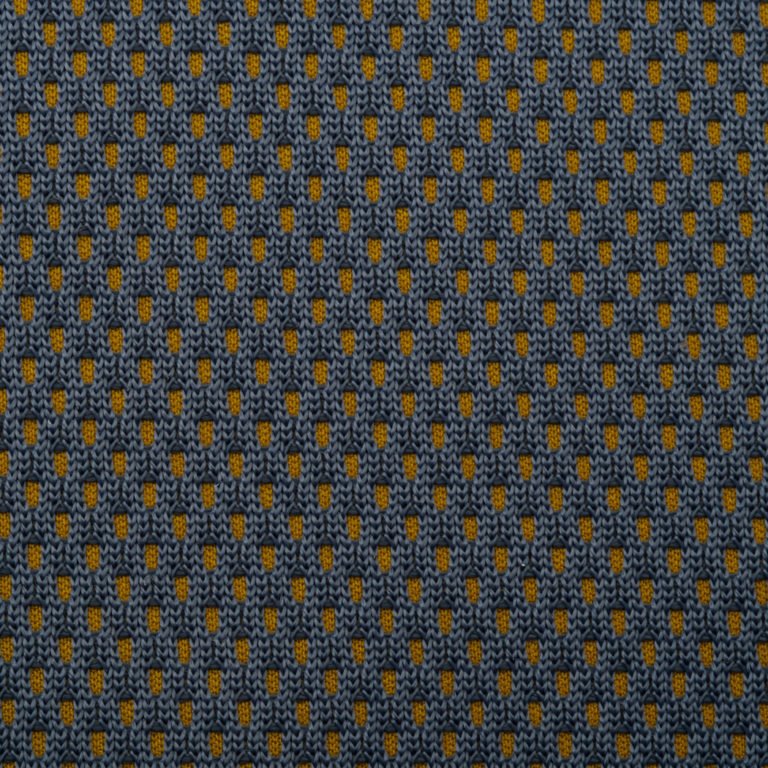

After analyzing the four main requirements of the sling—fabric strength, stability, drainage and surface smoothness—we concluded that the fabric construction and the yarn choice required reengineering. We designed a stabilized, non-stretch fabric using high tenacity yarn chosen for its strength. The fabric was knitted to create a smooth, non-abrasive seating surface that promoted drainage. The new textile was also rated 30% stronger. All of this was accomplished with no price increase. An option to use an anti-microbial finish offered the added feature of improved sanitary conditions.

RESULT REALIZED

The patient lift sling supplier replaced the fabric of the sling seat, and significantly reduced their risk exposure while at the same time offering a more comfortable seating surface.

Reach your most challenging

textile goals with confidence.