PROBLEM SHARED

A reputable company in the orthopedic industry wanted to produce a high-grade arm sling to increase comfort for the patient and enhance innate properties to the sling, for example make it less prone to absorb bacteria from sweat and dirt. As a US manufacturer, they sought a supplier with the same values they held and manufacturing facilities in the US.

PROBLEM SOLVED

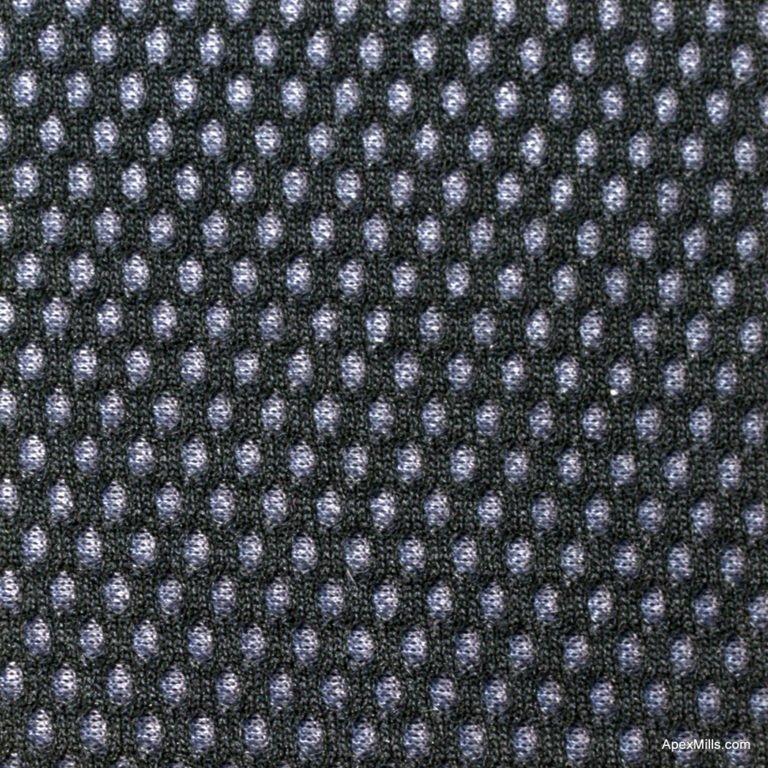

Analyzing the problem with the customer, Apex Mills’ fabric specialists developed a lightweight 3D spacer fabric with a textured polyester surface and an anti-microbial, moisture wicking backing. The unique yarn construction paired with the ability to use two different fabrics with a springy mono-filament in-between, enabled our customer to achieve their objectives while keeping the cost of production down.

RESULT REALIZED

The new sling proved successful, yielding positive feedback from patients and orthopedic specialists alike. As a result of the accolades received, the sling has become an approved item by Medicare and Apex Mills is partnering with the customer in their product development planning.

Reach your most challenging

textile goals with confidence.