PROBLEM SHARED

A leading supplier of life jackets was experiencing two problems with the fabric it was using as a liner. The mesh was too coarse and abrasive against skin, and the thickness of the fabric made it difficult for the sewing operators to work with, ultimately reducing production efficiency. An additional consideration was that the fabric required Underwriters Laboratory approval.

PROBLEM SOLVED

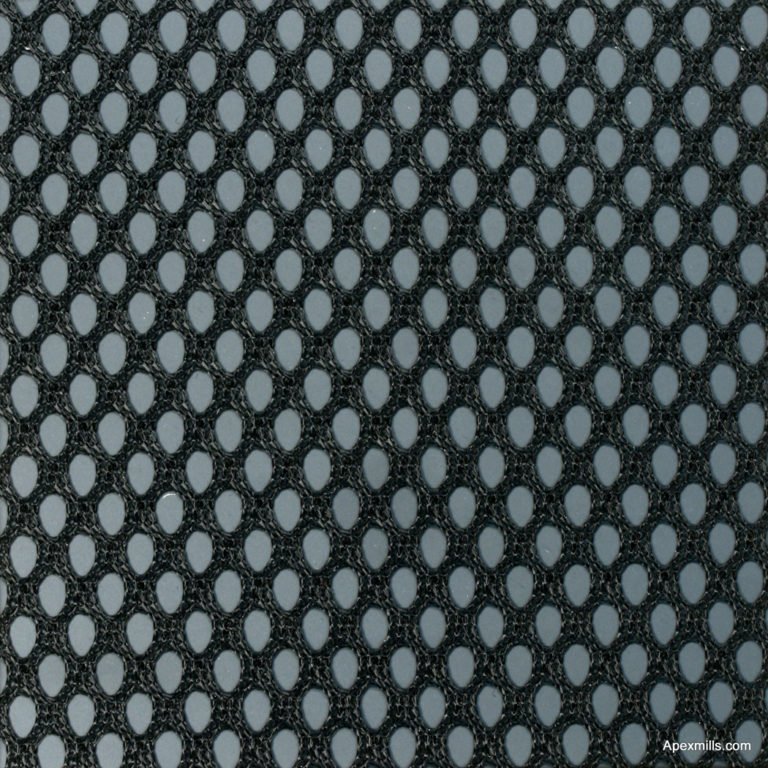

After extensive consultations with the customer, the existing fabric was knitted on a coarse gauge machine with large openings, thick stitches, and heavy yarns — the combination of which made for a very rough fabric. Using a finer gauge knitting machine and lighter weight yarns, we produced a smoother mesh with a smaller opening that still allowed for ample water drainage. The fabric was dyed and finished to meet UL standards and was a less expensive alternative to the original mesh.

RESULT REALIZED

The customer evaluated, approved and adopted the fabric, which continues to remain less expensive than the cost of the original fabric.

Reach your most challenging

textile goals with confidence.