PROBLEM SHARED

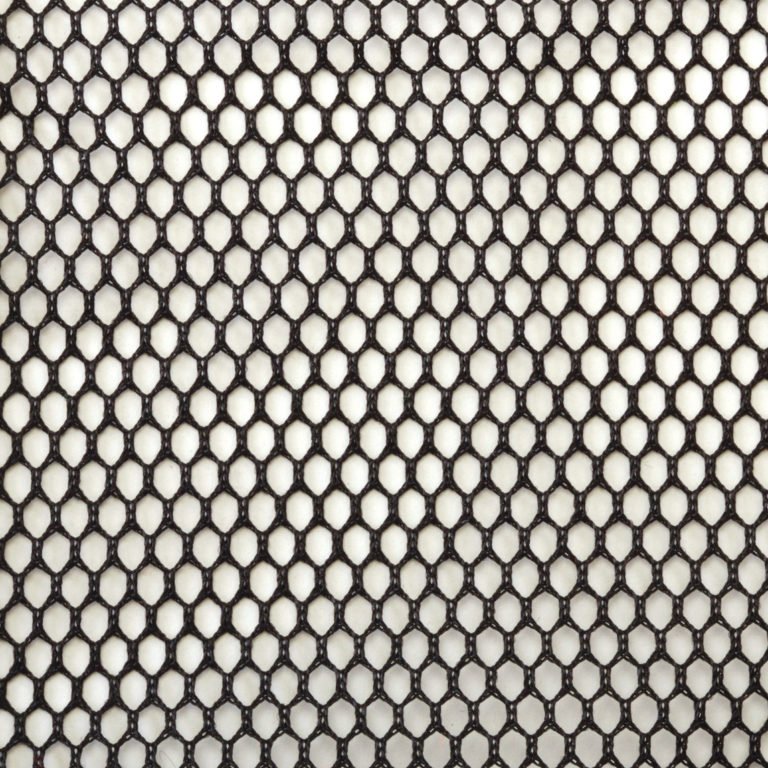

One of the largest manufacturers of reflective tapes used by police, firefighters and other safety personnel, needed a substrate fabric incorporating a costly flame retardant treatment to meet its flammability standards.

PROBLEM SOLVED

The specification was reviewed focusing on the flame retardant characteristics of the component yarns, finishes and reflective substances being applied by the customer. With the customer’s cooperation, untreated versions of the substrate were tested.

When the inherent flammability characteristics of the polyester substrate fabric were combined with those of the customer’s reflective substances, the fabric passed all required tests. The costly flame retardant treatment was found unnecessary.

RESULT REALIZED

The resulting simplification of the legacy specification allowed the customer a significant cost reduction for its substrate fabric

Reach your most challenging

textile goals with confidence.