Nylon is a synthetic polymer known as polyamide produced through a chemical process called polymerization. It was developed by the DuPont company in the 1930s and quickly became popular as a substitute for silk in various applications. In the textile manufacturing process, nylon chips are melted and extruded through spinnerets and spun as filaments. The filaments are joined together using heat, twisting, or intermingling with other filaments to make nylon yarn.

Denier is a key term in the textile industry. Denier represents the weight in grams of a 9,000-meter length of fiber or yarn (g/9k). Typically, the lower the denier, the finer the yarns. Denier types vary from fine, micro, standard, to heavy, each with its specific applications and characteristics used from sheer stockings to luggage.

Nylon is a man-made yarn that is widely used in textiles due to its high tensile strength, durability against abrasion, and versatility. Here are some key points about nylon yarn used in textiles:

Overall, nylon yarn remains a popular choice in the textile industry due to its combination of high tensile strength, durability, comfort, and versatility.

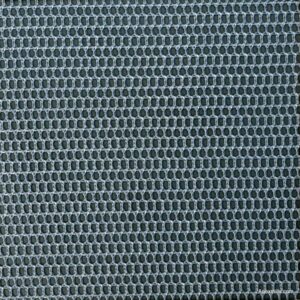

Figure 1 Raschel Knit Mesh style TP21 is made of Berry-compliant nylon type 6,6.

It is MIL-C-8061 compliant for MOLLE systems, safety apparel, tactical gear, seat cushions, and medical pack components.

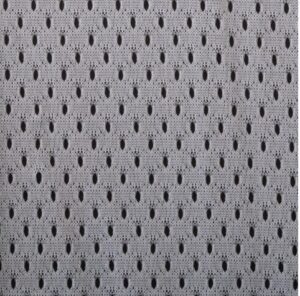

Figure 2 Apex Mills stretch raschel knit style 90312 is a blend of nylon and spandex yarns featuring excellent stretch, flexibility, and fit properties. Its superior capabilities to recover to its original shape make it ideal for compression garments, sportswear, swimwear, and shapewear where flexibility and shape retention are required.

Figure 3 Mesh Netting style RC47N is made of Berry-compliant Nylon type 6,6. and is military-specified for tents and other applications.

Many organizations within the medical, military, apparel, contract furniture, footwear, and sports industries depend on Apex Mills for innovative textile products. Our fabric specialists are committed to delivering results you can depend on. If you’re ready to get started, contact our team online to learn more about our solutions for your specific application.

Figure 4 Mesh/Netting style PV10 above is made of fire retardant-treated nylon for aerospace and defense, manufacturing, safety, and protection applications.

Figure 5 Mesh/Netting style NL50 is used for apparel, manufacturing, and military applications.

Reach your most challenging

textile goals with confidence.