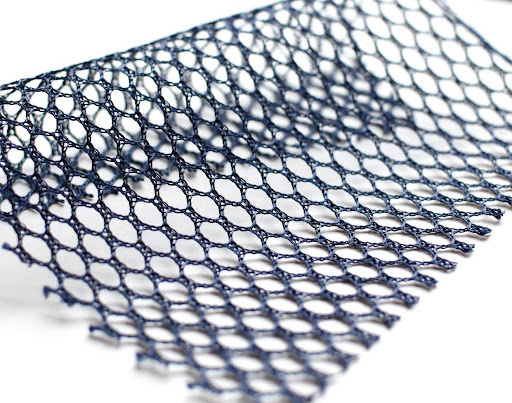

Mesh fabrics, also known as netting, can be designed and manufactured in an almost unlimited variety of shapes and sizes with uniform openings, allowing for lightweight breathability and enormous versatility. One key advantage is their strength-to-weight ratio, which enables them to be remarkably lightweight yet rugged, tear-resistant, and indispensable across many industries.

Mesh fabric is not just a textile but a versatile solution to many practical needs. From personal insect protection that allows the skin to breathe to military tactical vests that reduce precious weight from a soldier’s load, mesh or netting fabric serves various end uses. Understanding the properties of different fabrics and their applications ensures you can choose the suitable textile for your needs.

Netting or mesh fabrics have an open knit pattern that creates a network of evenly spaced gaps or holes that can be fine or coarse, depending on the fabric’s design—a mesh construction results in a breathable, lightweight fabric for ventilation applications. The fabric can differ in weight, thickness, color, and finish.

Mesh can be rigid, stretchy, or something in between. Polyester or nylon is often used for rigid mesh properties. We offer a combination of stretch nylons and polyesters with a balance of properties. Fabric can also be made with polyester/spandex, nylon/spandex yarns, or elastomultiester yarns for even greater stretch and recovery properties.

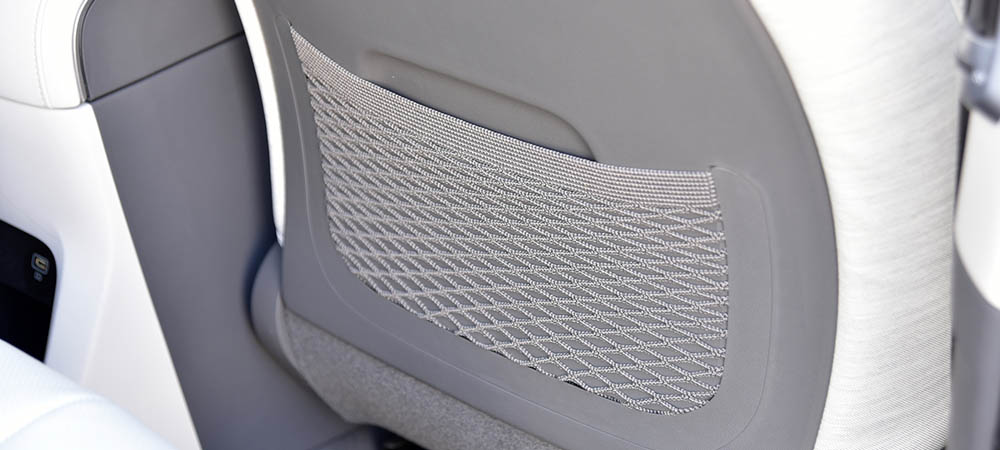

Along with breathability, mesh fabric can be designed and manufactured with large hole sizes that offer high visibility, making it easy to see through. The increased transparency makes this material a preferred choice for applications that include:

Car seat pockets like the one above are made of mesh fabric.

Mesh fabric can contain different yarns with various tensile strengths to meet the application’s needs. These yarns include polyester and nylon. The chosen options will impact the fabric’s load-supporting ability, measured in pounds per square inch (PSI).

The flexible construction allows product engineers to adapt the mesh fabric to the strength required by the application. For example, some yarn offers high strength-to-weight ratios, making it ideal for manufacturing durable sporting goods and protective wear.

If you are purchasing high-quality mesh or netting fabric, look for these features:

Various types of mesh fabrics are available. For example, mainstream options include tulle and a heavy-weight mesh suitable for military MOLLE vests. Tulle is a soft, delicate, light netting fabric made from man-made fibers such as polyester and nylon and is often used in wedding veils and gowns.

More durable options include mosquito netting, medical mesh, support garments/braces and spacer mesh for contract furniture and consumer goods.

The most commonly available mesh fabrics are made of synthetic yarn knitted into a mesh pattern. Knitting involves interlocking the yarns together, which enhances the capabilities of the final fabric and allows it to meet stringent requirements for various industries.

Additional benefits of polyester mesh include:

Nylon is a synthetic polymer with high tensile strength, excellent resistance to wear and tear, and good elastic qualities. It is made from nylon fibers derived from petroleum products. Nylon mesh is known for its strength, resilience and elasticity.

There are various types of nylon depending on their chemical synthesis, and are classified according to the number of carbon atoms per molecule:

You may hear the term power mesh or power net in mesh fabrics. Power mesh is a specialized fabric with superior durability, support, and elasticity. It is soft, lightweight, and has four-way stretch. The open structure offers excellent comfort, making it a good choice for shapewear and compression garments.

Specific power mesh applications include:

Apex Mills offers lightweight, tear-resistant netting and mesh fabric favored by Fortune 500 companies and government agencies. Our selection includes flame-retardant nylon mesh, stretch nylon, and elastomeric fabrics. When you partner with Apex Mills, you can expect the following innovative approach:

Netting and mesh fabrics have multiple applications and benefits across diverse industries, including medical, military, apparel, contract furniture, and industrial sectors. Their versatility and customizable characteristics will continue to drive innovation, leading to new uses and advancements.

At Apex Mills, we are ready to take on your most challenging textile goals, backed with an ISO 9001:2015 certification for quality management. We work with you to develop the right solution for your needs, using an Application Driven Design approach that results in innovative fabric formations. With expansive facilities and experienced local employees, we work around the clock to meet your textile needs. Contact us today for specialty fabric and textile innovation.

Reach your most challenging

textile goals with confidence.