In the textile industry, knitting is a technique used to create fabric by interlocking loops of yarn. It has played a vital role in textile manufacturing, evolving from a handcraft into a key industrial process. Today, modern knitting techniques paired with advanced knitting machines form the backbone of industries producing everything from everyday clothing, technical textiles to 3-D fabrics used in medical, automotive, aerospace, military, footwear, furniture, filtration, moisture-wicking sportswear, protective coverings and stretch fabrics.

There are two main knitting methods and types of knit fabrics — warp knitting and weft knitting. Circular knitting is by far the main type of weft knitting. Each method has its own characteristics, benefits and applications. Understanding these techniques and how they affect a fabric’s performance will help you decide which type is right for your application. For this discussion, we will be focusing on circular knitting as the form of weft knitting.

Machine innovations have revolutionized the textile industry, making mass production more efficient while allowing for intricate patterns and textures previously not achievable by hand. We now use machines to create weft and warp knits, the two basic types of knit fabrics. The main difference between these is the direction of the yarn loop. For warp knits, the loops are formed down the length or warp direction; for weft knits, the loops are formed across the width or weft direction.

Knit fabrics are popular in the fashion and textile industry due to their comfort, versatility and physical flexibility. Choosing between these techniques depends on the final product’s intended use. If you need stability and durability, opt for warp knits, either are flexible. For large production runs, warp knits are best. Weft knits have advantages for added stretch and conformability.

The yarns run vertically or parallel to the fabric’s length in warp knitting. A typical knitting machine can have 4000-5000 or more needles. Frequently, each needle in the knitting machine has its own yarn. Sometimes needles are skipped to create patterns. These yarns move in a zigzag pattern along the length of the fabric, forming loops over different needles as they traverse the needle bed, creating loops as the machine progresses. Warp knitting is highly efficient and fast, making it ideal for large-scale manufacturing. These interlocking loops ensure the fabric will not easily unravel, run, or fray.

The knitting process used in this fabric allows for customization in terms of design and structure. Multiple yarns, stitch patterns/jumps, and/or threading patterns are used to create complex patterns and textures, making warp knit fabrics versatile for many different applications.

Warp knit fabrics are often used for activewear, swimwear, medical, compression garments, military, automotive, composite reinforcement, and contract furniture due to their strength and ability to maintain shape. There are two main types of machines: tricot and raschel. Regarding design, tricot knits fit with larger volume production since they have more rudimentary stitch options. However, tricot knits typically run faster and smaller. Raschel knits have more flexible needle systems, which allow for a more complex fabric structure with open, lace-like construction and can feature heavier, often textured yarn inlaid between chain stitches made from finer thread. Raschel machines can allow fabric constructions with greater elongation when using a spandex yarn. As technologies mature, tricot machines have become more flexible, and raschel machines have become faster, blurring the lines previously set between them.

Warp knit fabrics have greater dimensional stability than weft knits, meaning they retain their original shape after stretching or washing. Their vertical construction also reduces the risk of fraying or unraveling, which is especially valuable in products that undergo heavy use. In addition, warp knits can meet more exacting specifications. This construction provides warp knit fabrics with the following properties:

Warp knits resist curling around the edges, which is beneficial in industrial applications demanding precise, clean edges.

As mentioned above, we will focus on weft knits for this discussion since they are the main type of circular knitting. There are other specialty weft knitting fabrics that are not as commonly used in the market. Weft knitting involves a single or a few yarns moving horizontally across the fabric, interlocking loops in rows below them. It is a method used in both hand and machine knitting. The loops are oriented horizontally, offering flexibility, and allowing more mechanical stretch. A classic example of this technique is knitted sweaters. Weft knitting is mostly used in everyday garments like T-shirts and socks, where flexibility and comfort are key.

Common weft knit fabrics include jersey and interlock (double knit). Jersey is the most popular weft knit used in everything from T-shirts to stockings. Interlock has more stretch and better recovery; it offers an interchangeable front and back appearance and a more refined look. Weft knitting is also used in home textiles like blankets and upholstery fabrics.

Weft knit fabrics are known for their comfort and versatility thanks to the following properties:

While both knitting techniques offer numerous benefits for specific applications, understanding their technical differences and how they impact fabric performance is essential. Key performance metrics include elasticity, durability, production speed, and fabric stability, all of which differ based on the knitting method.

Both warp and weft knitting methods follow unique production processes, resulting in fabrics with different properties and one commonality — interlocking loops of yarn that create fabric.

Additional structural similarities include:

Whether you need textiles for shapewear, uniforms, or insect protection, understanding the structural differences between various knitting methods will help guide your fabric choices. It will also help ensure the final product is functional and aligns with its intended use.

| Warp Knitting | Weft Knitting | |

| Flexibility | Warp knitting requires synthetic yarns. | Weft knitting can use almost any kind of yarn, including natural and spun yarns. |

| Yarn Direction and Loop Formation |

Yarns run vertically, also known as “warp-wise,” creating a stable, open fabric. | A single or multiple yarns run horizontally, in the “weft direction.” The interlocking loops give the fabric more stretch in both directions. |

| Stretch and Stability |

Vertical loops create a fabric that has more stretch and is more dimensionally stable. |

Horizontally running yarns make the fabric very stretchy but less stable. |

| Machinery and Production |

This method uses a specialized warp knitting machine with multiple needles creating fabric simultaneously across the width of the machine. Warp knits can meet exact specifications and be produced at very high rates. |

Machines used in this technique are less complex and take up a smaller footprint than their warp knitting machine counterparts. |

| Applications | The stability and durability of warp fabrics makes the technique ideal for sportswear, medical compression, military, industrial, contract furniture, automotive, and aerospace among other applications. |

The stretch and flexibility of this fabric makes it ideal for everyday apparel. |

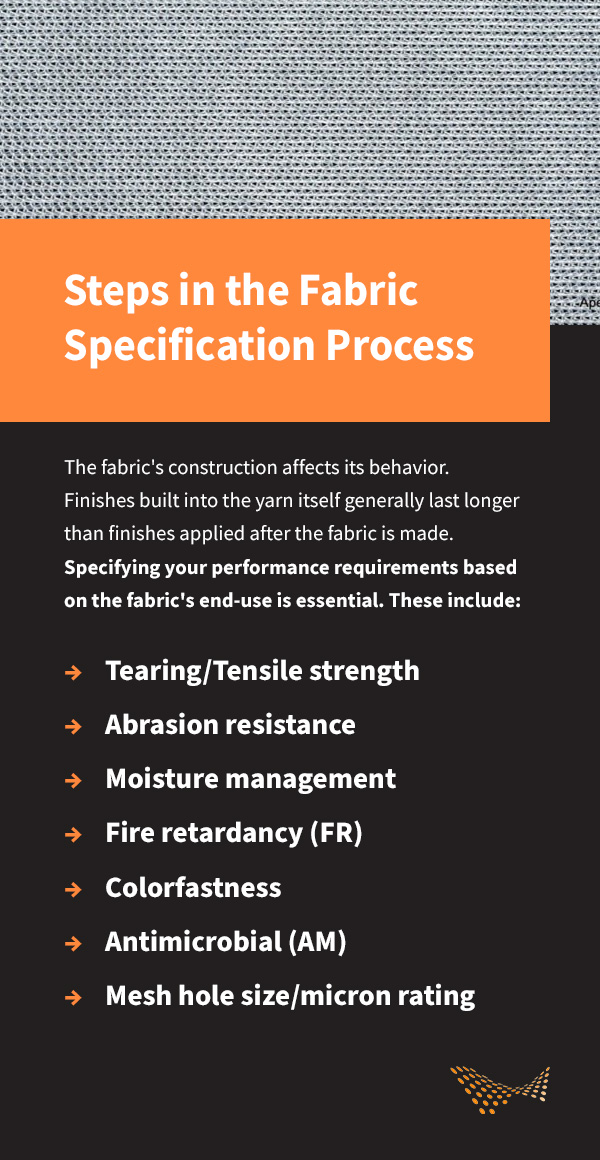

Selecting the right textile for your application starts with understanding all your fabric performance and aesthetic requirements and the pros and cons of various fabric constructions, which are critical in their durability, function, and feel.

The first step in fabric specification is defining the textiles’ end-use. The requirements differ significantly depending on whether the fabric is for upholstery, industrial use, or outdoor gear. Fabric for athletic wear, for instance, needs moisture-management properties and breathability, while upholstery demands durability and some stain resistance.

The fabric’s construction affects its behavior. Finishes built into the yarn generally last longer than finishes applied after the fabric is made. Specifying your performance requirements based on the fabric’s end-use is essential. These might include:

You may also find a fabric’s sustainability properties meaningful. Recyclable, biodegradable or low-energy fabrics are increasingly popular as they help reduce environmental impact.

Apex Mills designs and manufactures solid knits, mesh, netting, 3D spacers and stretch fabrics to suit your needs. Our fabrics are warp knitted with interlocking stitches and favored by Fortune 500 companies and government agencies. Partnering with us ensures you receive:

Knitted fabrics generally offer flexibility, breathability, and stretch. Weft and warp knits also have their benefits, but warp knits stand out for their superior durability, strength and stability.

At Apex Mills, we take on your most challenging textile goals, delivering warp knit fabrics for a wide range of industrial, military and healthcare applications. Our team works with you, using a unique application-driven design method to develop the perfect solution for your needs. All our fabrics are American-made — we engineer, test, and produce your textile in our expansive North Carolina and Virginia facilities. Our employees have over 150 years of combined experience.

Contact Apex Mills today, and enjoy specialty fabric and textile innovation at its finest.

Reach your most challenging

textile goals with confidence.