Apex Mills is an American warp-knit textile manufacturer with over 80 years of experience serving a broad range of industries – from aerospace and defense to medical/rehabilitation and orthopedics, and from military, safety, and protection to contract furniture and more. Our knowledgeable team, which has more than 150 years of experience combined, collaborates with engineers and product designers to produce textiles adhering to strict quality standards. We use an application-driven design approach that provides in-person collaboration, on-site developments, and quick responses to meet your exact specifications and product goals.

As experts in fabric craftsmanship across industries, we can collaborate with you throughout each production phase, from concept to finished fabric to enhance the marketability and profitability of your product.

Apex Mills offers textile solutions to serve the needs of a broad industry range, including:

Apex Mills works continuously to develop technically advanced solutions that solve the challenges faced in military, defense, and aerospace applications. Our products are integral to many aerospace operations, including the national space program and satellite development. We use phase-changing and temperature-controlling materials that can help absorb heat, or keep a person cool during space flight.

Our fabrics can serve as advanced insulation solutions for spacecraft to function outside the Earth’s atmosphere. Our multi-layer insulation (MLI) fabric is a lightweight option with several layers of film and netting that meets or exceeds standards for air and spacecraft, including the insulation requirements for NASA missions. Our relationship with NASA exemplifies our application-driven design approach and our ability to develop effective customized solutions.

Many facilities in the healthcare industry rely on fabrics and anti-microbial and chemical-resistant finishes from Apex Mills to deliver high protection, uniform compression, and shape conformity to meet the most challenging fabric goals. Our fabric applications include wound care, compression garments, hospital cubical curtains, patient lift slings, smart bandages, protective covers with high abrasion resistance, and equipment protection.

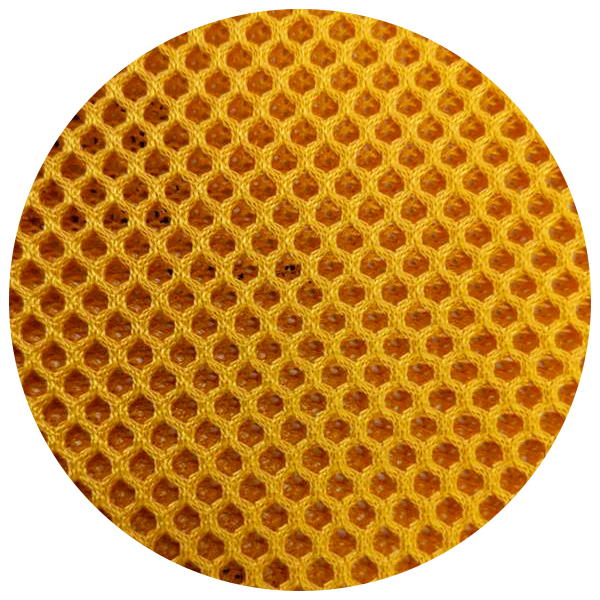

Product engineers use our anti-microbial fabric finishes to create solutions with self-sterilizing features that help prevent odors and bacteria growth. A good example of this fabric and finishing treatment is our Prop 65-compliant cubical mesh that meets Proposition 65 California government requirements to provide a safe and reliable fabric for hospital environments. Its exceptional durability, strength, and stability have made our engineered fabric an industry leader.

Another example of Apex Mills’s technical fabric for healthcare applications is our innovative auxetic which thickens and strengthens when under stress. Characterized by its negative Poisson ratio, this technical fabric will not “neck-in” when stretched – and thickens when elongated. Apex Mills’ innovative auxetic fabric conforms to shape solving the problem of sagging, and fabric thinning out, or necking in under stress and stretch for consistent, confident, and durable fabric recovery.

Our chemical-resistant finishes minimize fabric damage from dangerous substances. Many companies in the healthcare sector choose protective clothing made from our fabrics to keep their workers safe. Our engineering team regularly works with medical professionals to develop custom solutions for various specialized applications requiring fabric strength, stability, drainage, compression, stretch, abrasion resistance, and surface smoothness.

We supply a large range of textile products to meet the ever-changing expectations of the contract furniture industry. Our 3D spacer fabrics feature two fabric surfaces with an entanglement of yarns in between for dimension to provide varying levels of cushioning for body-support furniture such as office chairs and cushion pads. Besides offering superior breathability, absorbency, and resiliency, our fabrics can be custom dyed in our automated color lab. Our world-class dyeing and finishing operations ensure consistency and improve sample matching – making it easy to duplicate our customers’ previous colors and changing needs.

Our team helps extend a product’s life span by using various compositions, patterns, and finishes designed to meet our customers’ specific applications. We offer abrasion-resistant, fire-retardant, antimicrobial, and moisture-management fabric finishes to provide durable solutions for the most challenging textile applications.

At Apex Mills, we consider sustainability in all our products and business processes. Our ISO 9001:2015 certification is a testament to our commitment to continuous improvement. We have designed many of our fabrication processes to minimize material waste and reduce our carbon footprint. Our Insight Textiles plant in Woolwine, VA diverts 92.3% of all manufacturing waste from landfills, and our Apex Aridyne plant in Graham, NC recycles over 25,000 lbs. of paper, nylon, and paper per month.

Our fabrics can be designed with degradable yarns, bio-based yarns, ocean waste yarns, industrial waste yarns, and sustainable yarns from recycled plastic.

Apex Mills offers customized textile products to solve the challenges many of today’s most successful businesses face. Our engineering and design teams will work closely with you to address your requirements and develop the most practical, effective solutions.

Some examples of our solutions include:

Fabric for a medical lift sling supplier: Apex Mills reengineered the supplier’s original fabric and developed a 30% stronger textile that promoted drainage and offered more support without increasing the price.

Fabric for military physical training uniforms: Our Berry-compliant fabrics manage moisture and odors to make high-performance end-use apparel comfortable and lightweight.

Footwear linings: We created a soft, smooth fabric that exceeds industry standards to reduce friction between the sock and shoe. Our customer currently offers the fabric as one of the leading performance footwear linings available today.

Golf screen + projection fabrics: We’ve engineered fabrics with the ideal cushioning for absorption, strength, opacity, and image brightness. Our tight-knit fabrics provide smooth surfaces for sharp image clarity, reinforced durability, and noise-dampening.

If you’re interested in learning more about our industries and how our American-made products and services can benefit your operation, the experts at Apex Mills can assist you. Discover why companies across various industries consistently choose our solutions over competing brands. Call 516-239-4400 or contact us online today to get started.

Reach your most challenging

textile goals with confidence.