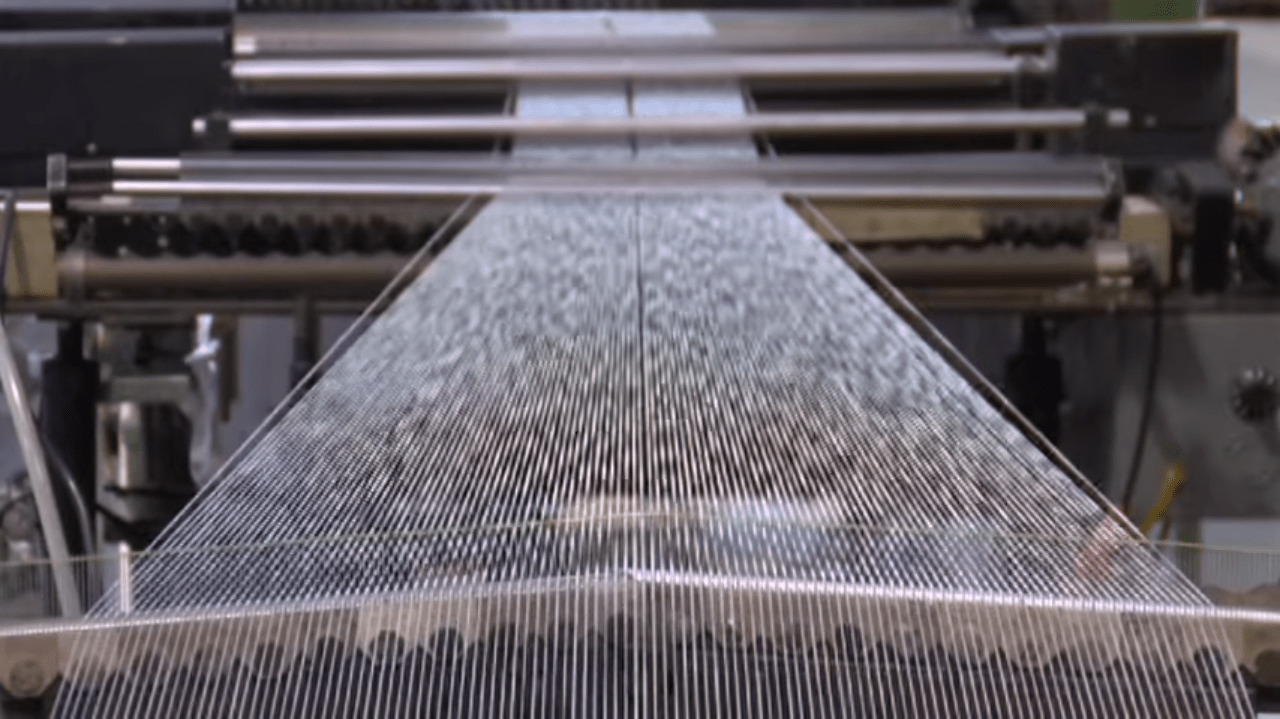

Abrasion resistant fabric withstands surface wear from rubbing, extending the life of a product and protecting the person who wears it. Textiles that retain their construction during extensive wear are sought by companies whose products depend on reliable safety and wearability. Technical textile suppliers, such as Apex Mills, create performance fabrics that demonstrate exceptional load-bearing properties and “toughness” – the tenacity and elongation of the fabric needed to break the fibers.

Find Your Custom Textile Solution Today!

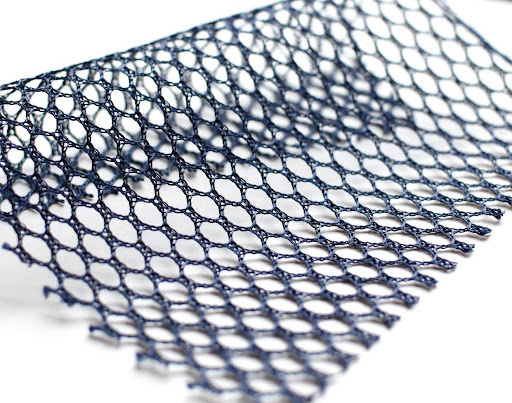

Depending on the application, abrasion resistance in textiles can be achieved with varying compositions, patterns and finishes that best meet the specifications and requirements from customers. For instance, in footwear, it is important that the fabric can flex without the fiber breaking. In contrast, geotextiles need the surface of the fabric to withstand abrasion caused by erosion.

Apex Mills is a high abrasion resistant fabric manufacturer with experience making custom-engineered textiles. We aim to solve your problems through extensive research and development of fabrics that will consistently meet your expectations. Properties of this fabric include:

Our material stands up to long-term use and will not demonstrate flex fatigue. With application-driven design informed by our expertise, we give you the type of innovative, high-quality fabric you need to pass on to your customers.

A number of industries benefit from abrasion resistant fabrics. You can employ them in a range of products that need to be tough and rub resistant. They won’t pill upon laundering and can even withstand exposure to UV lighting. You might find these textiles in the following applications:

Abrasion-resistant warp knit fabric is easily molded. It can be a focal point of everyday items such as backpacks, motorcycle jackets/gloves, footwear or camping equipment and other outdoor devices. Fabric thickness, coating, texture and more all help determine the strength and utility of the fabric.

Apex Mills partners with engineers and product designers to create textiles to their specifications and meet the needs of their businesses. We have developed a variety of fabrics, from eco-friendly and Berry compliant to antimicrobial, and our abrasion-resistance textiles fulfill a need among companies for more intricate designs. We love stepping up to the challenge and working with our customers to meet their unique requirements.

Our textiles are fully tested. Using a Taber machine, we can test a fabric’s wear resistance. The Taber test involves mounting a fabric sample onto a turntable that rotates at a fixed speed. Two wheels, which are applied at a specific pressure, are lowered onto the fabric’s surface and spins, rubbing the fabric against the wheels. The number of cycles the fabric can endure without breaking the fibers indicates the level of abrasion resistance.

Located in the United States, our American-made materials can be customized to meet your needs, such as sound absorption or breathability. We can develop CAD drawings of a fabric construction before a needle touches yarn, saving you both time and money. Get in touch with us today to learn more about our capabilities. You can start by filling out our questionnaire form, visiting our website at www.apexmills.com or calling us at 1-516-239-4400.

Reach your most challenging

textile goals with confidence.