3D spacer fabrics go above and beyond to provide solutions for a wide variety of applications. If you’re looking for an innovative fabric that’s breathable, cushioned, absorbent, resilient – meaning it keeps its shape, soft to the touch, and pleasing to the eye, then look no further.

A sustainable alternative to foam, spacer fabrics offer greater durability, retain their cushioning properties, and are recyclable, making them better for the environment. Checking every box, Apex Mills is the expert at constructing the perfect spacer fabric for your product.

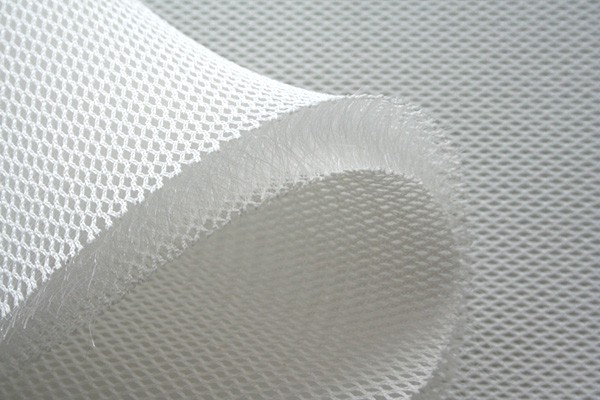

3D spacer fabrics have three layers: two surfaces (a face and a back) that sandwich a layer of vertical filler yarns to provide varying levels of thickness for volume and cushioning. Each layer can possess unique characteristics, making the possible variations virtually limitless.

Considered a technical textile, spacer fabrics are engineered based on their end-use, with three main variables to consider. The first is fabric construction – the face and back of the fabric can be a solid knit or a mesh design. A mesh face allows for greater airflow, while a solid knit would enable the textile designer to apply a performance-enhancing additive to the center fibers, perhaps for insulation or molding properties. The fabric’s thickness can also be modified based on the application’s needs. Our spacers typically range from 1.5mm up to 10mm in thickness.

The next variable is the choice of yarns selected to address the performance goals of the textile. You might want a polyester or nylon fabric for strength and durability or a yarn with silver, copper, or zinc for inherent antimicrobial attributes. Yarns can be sustainable, made from recycled plastic chips, or even biodegradable.

Spacer fabrics are made on double-needle bar (DNB) machines. These machines have two independent needle bar systems, each used to knit a side of the fabric. By traversing yarns, called spacer yarns, between the two fabric faces, the machine creates the innermost layer. Monofilament yarns are often used for the innermost, or pile layer, as they are more resilient and stiffer, enabling a greater separation of the two faces. Multifilament yarns can also be used, but they are softer and limit the thickness of the spacer to about 4mm.

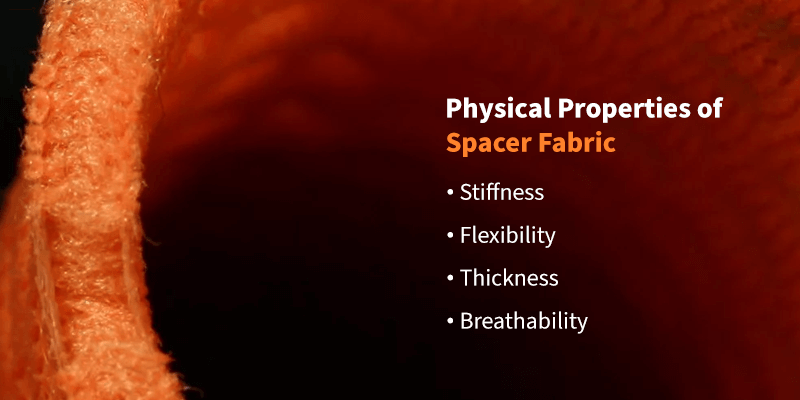

Spacer fabrics provide volume without weight; a benefit sought after by product designers across industries. They can be made with varying degrees of flexibility, stiffness, and breathability and contain acoustic, insulating, and cushioning properties.

Because spacer fabrics are highly customizable, they appeal to product designers across industries.

You can customize select spacer fabric faces to be waterproof. Though 3D fabrics are naturally porous, you can coat them with waterproofing layers to increase their moisture resistance. Waterproof spacer fabrics are especially valuable in the medical industry, as health professionals use them to dress wounds and protect them from getting wet.

Spacer fabrics are machine-washable, so products made from 3D spacers can easily integrate into everyday life.

3D spacer fabric is a viable replacement for foam in many industries. Foam degrades quickly and creates large amounts of waste. For a more sustainable option, you can choose spacer fabrics made from organic yarns, biodegradable yarns, or recycled yarns. For greater ecological sensitivity you can create colors with low eco-impact dyes. Find a textile manufacturer that will work with you to create quality products while reducing your environmental footprint.

3D spacer fabric is your best bet for durable, flexible, and versatile textiles. When you need custom, high-quality fabrics for any industry, count on Apex Mills to provide smart solutions.

We design, construct and test all our fabrics in North Carolina, and we approve every step of the process before you receive your custom fabrics. Fortune 500 companies and government agencies trust us, so learn more about how we can bring our expertise to your products.

For more information about our textiles or to get started with your specialty fabric design, contact us today!

Linked Sources:

Reach your most challenging

textile goals with confidence.