Golf is a favorite pastime for millions of people. With modern technology, enthusiasts can practice golf in any location, no matter the weather. Popping up at airports, shopping malls, sporting goods stores, and arcades, golf simulator screens make it possible for golfers to play indoors at any time.

Download Our Golf Screen & Projection Fabrics Brochure

As impact screens grow in popularity, so does the demand for high-quality fabric suited to display clear images and absorb impact. At Apex Mills, our fabric specialists (many of whom are golf devotees) partnered with leading companies in the simulator industry to engineer golf screen fabrics with the ideal cushioning for absorption, sound dampening, opacity, and brightness.

Golf Impact Screens – Perfect Edutainment

Golf impact screens have gained in popularity over the past 20 years. With continued advances in technology, indoor golf has become more lifelike with the added benefit of providing insight into your golfing strengths and weaknesses. Cameras and sensors enable golfers to receive an analysis of their swing along with the ball’s trajectory, distance, spin rate, and many other metrics. Overall, golf impact screens make it easy for anyone to learn how to golf or continue practicing on rainy days and throughout the cold winter months.

What Are Golf Impact Screens Made Of?

Polyester mesh is a good fabric choice since it’s lightweight, durable, and affordable. Varying levels of screen quality can be achieved by adding layers of polyester mesh, making the screen sturdier and preventing light from bleeding through. Nylon mesh is also a good option offering a touch more strength and durability; however, it can be more expensive. Most importantly, the fabric must be durable and able to withstand a ball hitting it at 200+ mph without tearing.

There are several key factors to consider when choosing the right fabric for a golf impact screen:

Choose Apex Mills for Quality Golf Impact Screen Fabrics

At Apex Mills, we provide companies with access to fabrics designed to meet the needs of golfers using simulator screens. All our fabrics are produced at our North Carolina and Virginia mills and are designed and tested for high energy absorption. We manufacture impact screen fabrics at an optimal 120-inch width and ensure they are highly durable for long-lasting enjoyment.

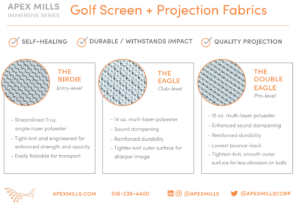

We’ve perfected our golf screen fabrics and offer different types and levels so manufacturers can meet all their customer’s demands.

Apex Mills – A Brand You Can Trust

Apex Mills is a respected brand trusted by Fortune 500 companies and government agencies such as NASA to provide quality products that meet the needs of our customers. We maintain high standards by delivering American-made, durable products. With over 80 years in business and a salesforce with more than 150 years of collective experience, we can custom design the perfect fabric solution for your product development.

Contact us today to let us know what you’re looking for in a high-end golf impact screen. We’ll be in touch to learn more about your needs before we start your project.

Contact Us Today For A Free Quote

Click here to download the Brochure

Reach your most challenging

textile goals with confidence.