You might notice many companies promote wicking properties and quick-drying features in their clothing products. What exactly does this mean, how do these features work, and are they worth paying extra for the added benefit? Let’s break it down.

Contact Us For Your Textile Innovation

Moisture management is the ability to transport moisture away from the skin to the garment’s outer surface and then cause it to evaporate. Moving moisture away from the body helps to:

There are three levels of moisture management technology — moisture absorbency, moisture wicking and moisture repellency:

Absorbency is the ability of a fabric to take in moisture. It’s an important property in textiles because it enables the moisture to be quickly collected in a concentrated area. However, fabrics that absorb well are prone to staining and retaining odor over time.

Wicking pulls moisture away from the body to the exterior surface of the fabric where it can evaporate more easily. Think of it as a transportation system, moving liquid up and away from your skin via tiny tubes, and releasing it to the outer layers of your clothing or into the air. Wicking helps to keep you dry, reduces chafing and inhibits the susceptibility to microbial growth.

If a textile is moisture repellent, it means that it is hydrophobic and pushes away moisture on contact. Water repellent fabrics are coated with a film on a molecular scale that gives them the ability to withstand above-average exposure to moisture without soaking through. Moisture beads up and rolls off the fabric, rather than being absorbed into the fibers.

Absorption is inherent in certain types of material, such as cotton, but cotton lacks the strength and durability found in synthetic fibers. Through nanotechnology, microscopic changes are made to the fibers to develop the desired textile characteristics in synthetic polymers. Apex Mills works with several nanotechnology companies to identify the best treatments for our textiles so that they meet the requirements of the application in which they are used.

Our DryRUN™ family of high-performance fabrics utilizes knitting constructions and finishes to optimize the benefits of moisture management while providing maximum comfort.

At Apex Mills, we have several moisture-absorbing, repelling and wicking textiles, including DryRUN™, DryRUN+™, DryRUNX™ and DryRUNa.m.™ Here’s a more detailed look at these moisture absorbency fabrics:

DryRUN™, our single process, multi-directional moisture management treatment, absorbs and spreads moisture over a larger surface, enabling liquids to dry more quickly. It’s used in various applications, including clothing, cleaning cloths, packaging supplies and filters. When moisture absorption is necessary, DryRUN™ delivers.

DryRUN+™ is a dual process, one-way moisture transport solution that is treated on both sides of the fabric. First, it wicks moisture away from the skin side up to the outer layer and then spreads the moisture over a larger surface for fast drying. DryRUN+™ keeps the wearer comfortable and accelerates quick drying.

DryRUNX™ offers extreme moisture repellency when you need moisture to roll off a fabric, leaving no wetness behind. By changing the surface of the fabric at the molecular level, moisture is unable to penetrate it and rolls off, keeping both the fabric and wearer dry and comfortable.

DryRUNa.m.™ combines absorption and wicking with an anti-microbial treatment. It catches moisture, moves it away from the skin and releases it for quick evaporation, and it also inhibits the growth of odor-causing bacteria on fabrics. It’s used in performance fabrics for your morning run, by servicemen in the military and for orthopedic braces and devices — the applications are limitless.

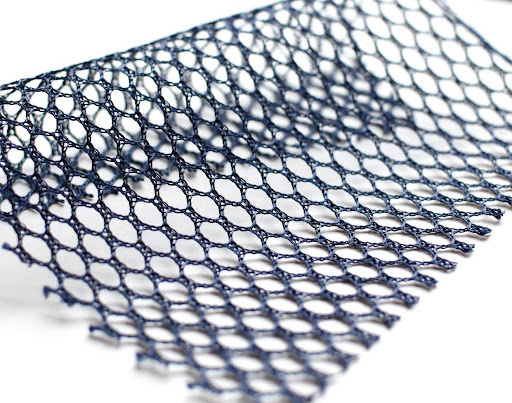

Since our founding in 1943, Apex Mills has been perfecting and innovating various types of industrial fabrics, including solid knits, mesh and 3D spacers. Committed to solving our customers’ problems through truly innovative, reliable solutions, we work with hundreds of companies across numerous industries to design and manufacture textiles that meet their specific needs.

Follow us on Twitter and LinkedIn and read our blog to stay up to date on industry news and innovations. If you have questions about a certain application you’re developing and need advice, contact us today to speak with an Apex Mills textile expert.

Similar Content From Apex Mills:

Reach your most challenging

textile goals with confidence.