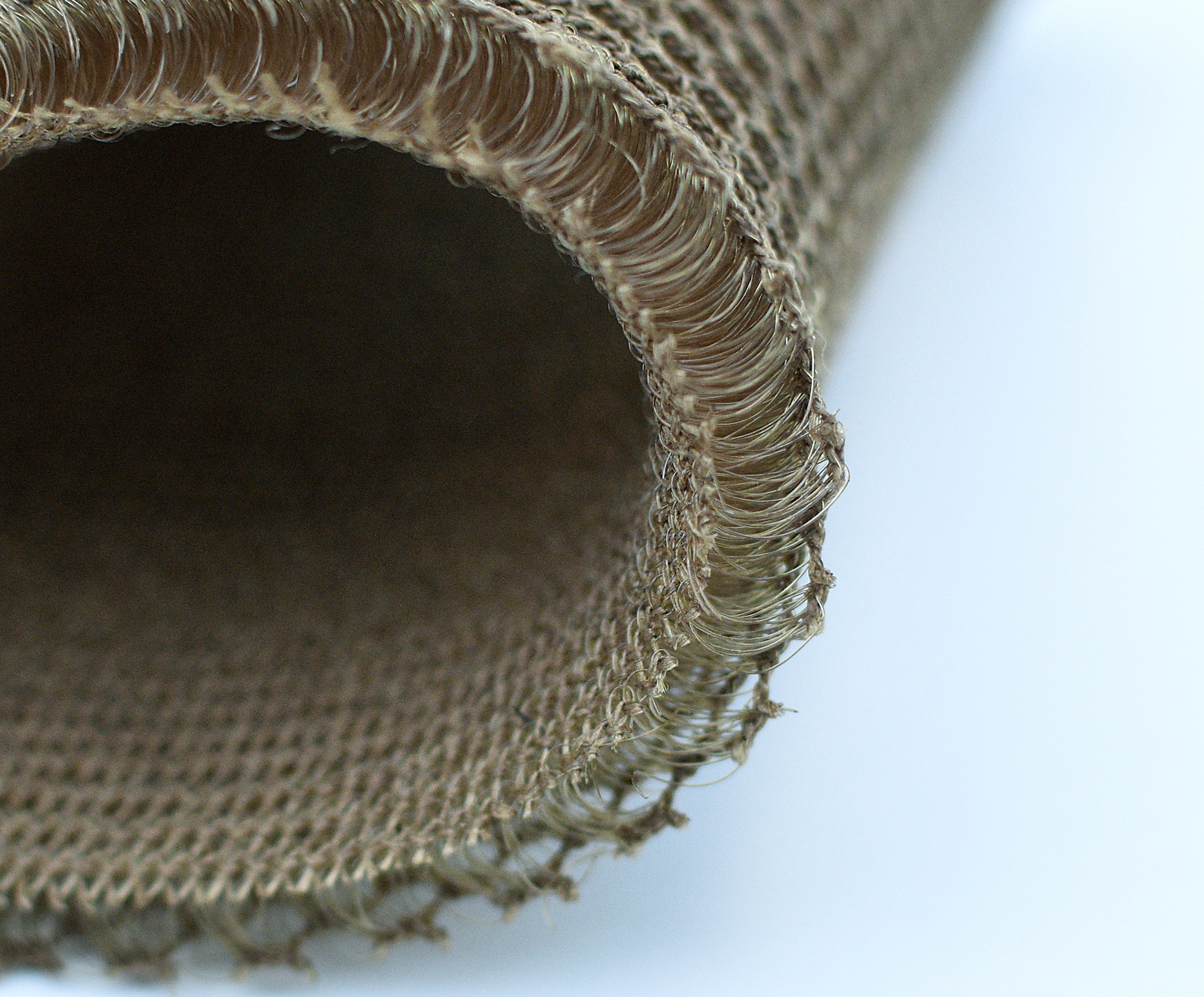

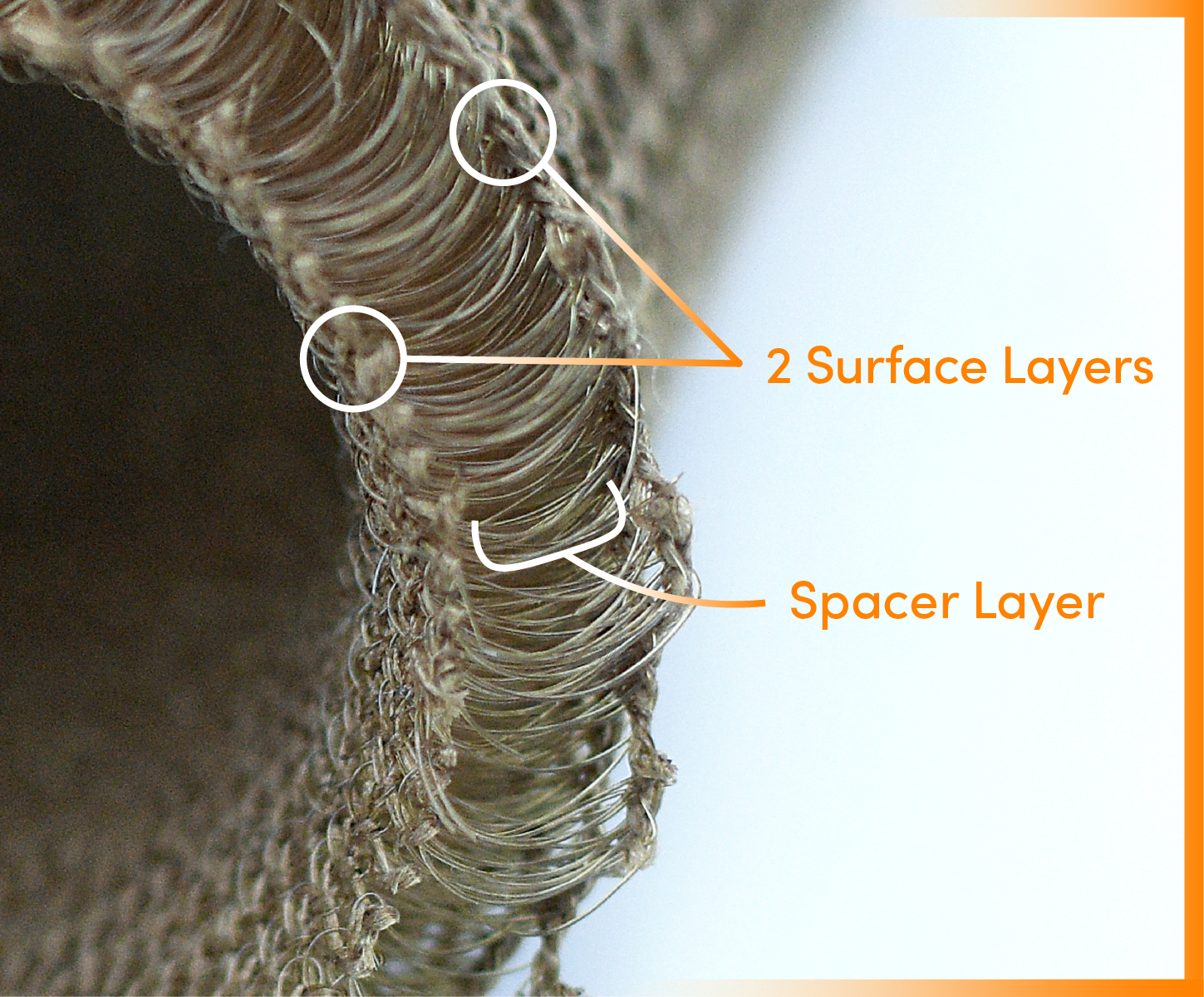

3D spacers, also known as “spacer” fabrics, are three-dimensional textiles with two outer layers of material surrounding a looping yarn (or pile) structure to provide key performance advantages.

The three-dimensional nature of these fabrics offers a range of interesting properties, including absorbency, breathability, cushion, loft, resilience, softness, and visual appeal. 3D spacer fabrics are commonly used in automotive materials, filtration, footwear, furniture, geotextiles, medical materials, military and tactical apparel, and sportswear.

Each layer of a 3D spacer fabric can provide unique characteristics, which gives the textile designer flexibility in terms of functionality. When specifying 3D spacer fabrics, there are three critical variables to consider:

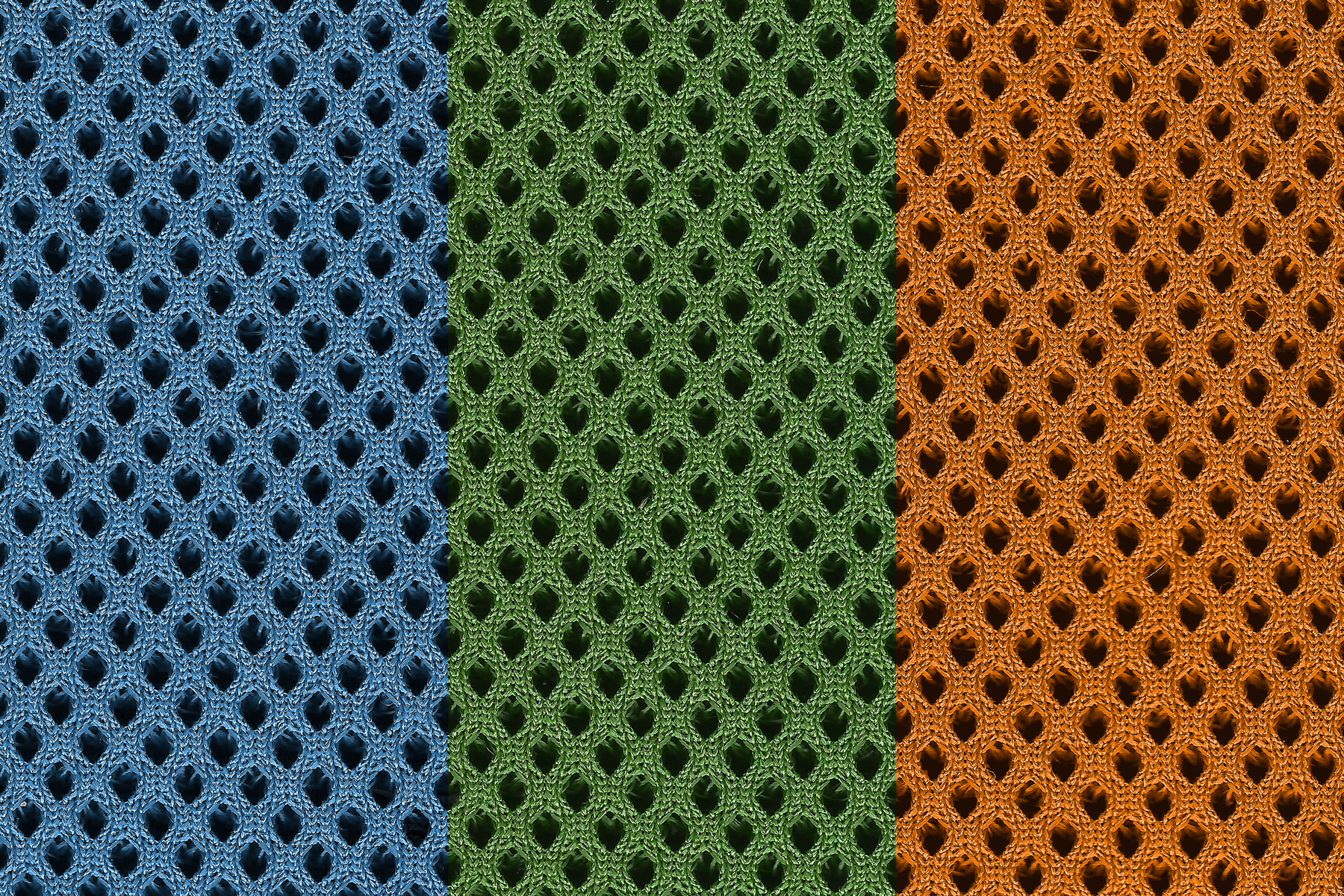

1. Fabric construction: The face and back of the fabric can be a solid knit or a mesh design. A mesh face allows for more airflow, while a solid knit, for example, enables the textile designer to apply a performance-enhancing additive to the center fibers, perhaps for insulation or molding properties. The fabric’s thickness can also be modified based on the application. For example, a thicker spacer fabric could provide fortified cushioning or added insulation.

2. Yarn selection: The textile designer may choose polyester or nylon for strength and durability. A silver, copper, or zinc yarn may be selected to provide antimicrobial attributes. Yarns can also be selected to achieve sustainability goals, e.g., using yarns made from recycled plastic chips or even biodegradable materials.

3. Finishing: The process/processes used to finish the fabric is vital to consider. Finishes can enhance utility, texture, and color, among other key characteristics. The finishing step(s) allows the designer to fine-tune the material to maximize its performance based on the intended end-use. (For a deeper dive into textile finishing, please check out our “Guide to Fabric Finishes.”)

3D spacer fabrics are made on double-needle-bar (DNB) machines. These knitting machines have two independent needle-bar systems, each used to knit a side of the fabric. The machine creates the innermost layer by traversing spacer yarns between the outer fabric faces. Monofilament (single strand/thread) yarns are often used for the innermost (or pile) layer, as they are more resilient and stiffer, which allows for greater separation between the two outer layers of the fabric. Multifilament (multiple strands/threads braided together) yarns can also be used, but they are softer and limit the thickness of the spacer fabric to about 4mm.

The unconventional three-layer structure of 3D spacer fabrics provides essential benefits, including:

Several aspects of 3D spacer fabrics can be designed to provide enhanced performance for specific applications:

Customized 3D spacer fabrics can deliver enhanced performance in areas such as:

Apex Mills delivers advanced, customized 3D spacer fabrics for various industries and applications, including aerospace, automotive, medical, military, and tactical apparel. Our 3D knitted spacer fabrics are manufactured following ISO 9001:2015 certification, ensuring safety and quality.

Our Insight Textiles facility in Woolwine, Virginia, strengthens our ability to manufacture innovative solutions, such as 3D spacer fabrics, and offers state-of-the-art fabric dyeing, finishing, and surface- treatment capability, including:

A standout feature of the Insight Textile facility is the cutting-edge dye lab, a hub for color innovation and development. The lab enhances our efforts to create custom colors and pioneer finishes.

Because 3D spacer fabrics are highly customizable, they appeal to textile designers across multiple industries.

3D spacer fabric faces can be designed for water resistance. While 3D fabrics are naturally porous, they can be coated with finishes to increase their moisture resistance. Water-resistant spacer fabrics are especially valuable in the medical industry, as health professionals use them to dress and protect wounds from getting wet.

Spacer fabrics are machine-washable, so products made from 3D spacers can easily integrate into everyday life. 3D spacer fabrics can be easily machine-washed in cold water, depending on the product. However, it is always recommended to follow the washing instructions on the product itself.

3D spacer fabrics are a viable replacement for foam in many industries. Foam degrades quickly and creates large amounts of waste. For a more sustainable option, 3D spacer fabrics can be made from organic yarns, biodegradable yarns, or recycled yarns. They can also be colored with low-eco-impact dyes.

Apex Mills designs, manufactures, tests, and approves all fabrics in our North Carolina, Virginia, and New York facilities. Trusted by Fortune 500 companies, law enforcement, and government agencies, we invite you to collaborate with us to address the needs of your specific application.

Reach your most challenging

textile goals with confidence.